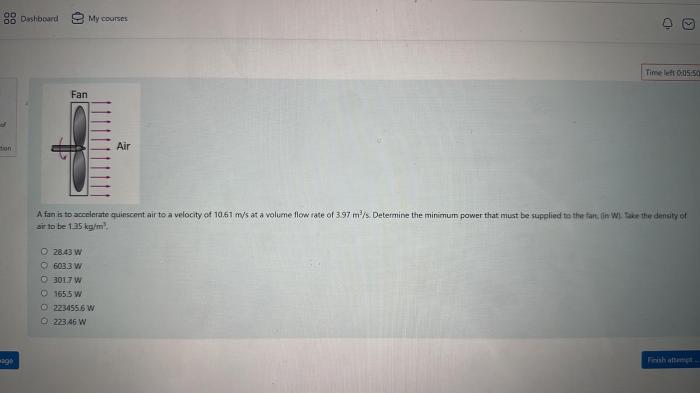

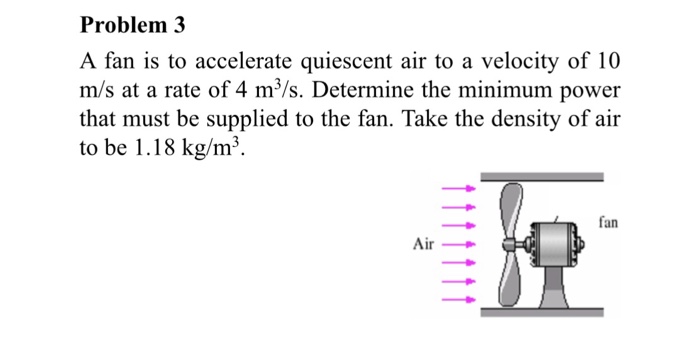

A fan is to accelerate quiescent air – A fan’s primary purpose is to accelerate quiescent air, making it a crucial component in various applications. Understanding the structure, performance, and applications of fans is essential for optimizing their use and ensuring efficient air movement.

This comprehensive guide delves into the intricacies of fan design, performance metrics, applications, control mechanisms, and maintenance practices. By exploring these aspects, we aim to provide a thorough understanding of fans and their role in air circulation and temperature management.

Fan Structure and Design: A Fan Is To Accelerate Quiescent Air

A fan is a mechanical device that accelerates quiescent air to produce a flow of air. It consists of several essential components:

- Blades:The blades are the primary components that generate airflow. They are typically made of lightweight materials such as plastic, metal, or composite materials.

- Motor:The motor provides the power to rotate the blades. It can be an AC or DC motor, depending on the fan’s design.

- Housing:The housing encloses the motor and blades and directs the airflow. It can be made of various materials such as plastic, metal, or composite materials.

- Mounting system:The mounting system allows the fan to be installed in various locations, such as on a wall, ceiling, or floor.

There are different types of fans, each with its advantages and disadvantages:

- Axial fans:Axial fans move air parallel to the axis of rotation. They are commonly used in applications where high airflow is required, such as in ventilation systems.

- Centrifugal fans:Centrifugal fans move air radially outward from the axis of rotation. They are often used in applications where high pressure is required, such as in industrial blowers.

- Tangential fans:Tangential fans move air tangentially to the axis of rotation. They are often used in applications where a wide distribution of airflow is required, such as in air conditioners.

The design of fan blades is crucial for efficient airflow. The shape, pitch, and angle of attack of the blades all affect the fan’s performance.

- Blade shape:The shape of the blades determines the amount of air that can be moved. A wider blade will move more air than a narrower blade.

- Blade pitch:The pitch of the blades refers to the angle at which they are set. A higher pitch will generate more airflow but will also require more power.

- Angle of attack:The angle of attack is the angle at which the blades meet the airflow. A higher angle of attack will generate more airflow but will also increase the noise level.

Fan Performance and Efficiency

Fan performance and efficiency are critical aspects in ensuring effective air movement and system optimization. Understanding the key metrics, influencing factors, and methods for calculating and improving efficiency is essential for selecting and designing fans for various applications.

Airflow Rate, A fan is to accelerate quiescent air

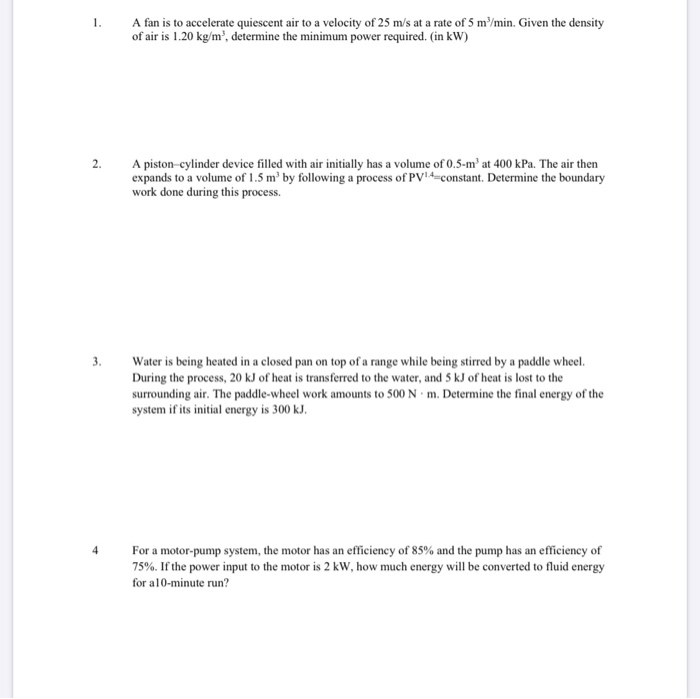

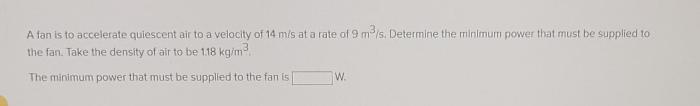

Airflow rate, measured in cubic feet per minute (CFM) or cubic meters per second (m3/s), represents the volume of air moved by the fan. It is a fundamental parameter that determines the fan’s capacity to provide air circulation and cooling.

Static Pressure

Static pressure, measured in inches of water (in. H2O) or Pascals (Pa), refers to the pressure difference created by the fan against system resistance. It is a measure of the fan’s ability to overcome obstacles and deliver air through ducts, filters, or other components.

Power Consumption

Power consumption, measured in watts (W), indicates the amount of electrical energy required to operate the fan. It is an important consideration for energy efficiency and operating costs.

Factors Affecting Fan Performance

Fan performance is influenced by several factors, including:

- Blade design: The shape, size, and pitch of the blades impact airflow rate, static pressure, and efficiency.

- Fan speed: Increasing fan speed typically increases airflow rate and static pressure but also increases power consumption.

- System resistance: The resistance encountered by the fan from ducts, filters, and other components affects airflow rate and static pressure.

Fan Efficiency

Fan efficiency is a measure of the ratio of airflow rate to power consumption. It indicates the fan’s ability to convert electrical energy into effective air movement. Efficiency is typically expressed as a percentage.

Efficiency = (Airflow Rate / Power Consumption) x 100%

Improving fan efficiency can reduce operating costs and energy consumption. Strategies for improving efficiency include:

- Selecting fans with high-efficiency blade designs.

- Optimizing fan speed to match system requirements.

- Minimizing system resistance by using efficient ductwork and filters.

Fan Applications

Fans are widely employed across various industries for ventilation, cooling, and air circulation purposes. Their applications extend to residential, commercial, and industrial settings.

In residential applications, fans are commonly used for:

- Providing ventilation in bathrooms, kitchens, and other areas prone to moisture accumulation.

- Cooling indoor spaces during hot weather, particularly in regions with limited air conditioning.

- Circulating air to improve indoor air quality and reduce stale air.

Commercial Applications

In commercial buildings, fans play a crucial role in:

- Maintaining comfortable indoor temperatures in offices, retail stores, and other public spaces.

- Ventilating large spaces, such as warehouses, factories, and auditoriums.

- Exhausting fumes and pollutants from industrial kitchens, laboratories, and other areas with potential air quality hazards.

Industrial Applications

In industrial settings, fans are essential for:

- Cooling machinery and equipment to prevent overheating and ensure optimal performance.

- Ventilating factories and workshops to remove dust, fumes, and other airborne contaminants.

- Providing air circulation in warehouses, distribution centers, and other large-scale industrial facilities.

Considerations for Fan Selection

When selecting a fan for a specific application, several factors should be considered:

- Airflow requirements: The volume of air that needs to be moved.

- Static pressure: The resistance to airflow caused by the fan’s environment.

- Noise level: The amount of noise generated by the fan.

- Energy efficiency: The fan’s power consumption and efficiency rating.

- Size and mounting requirements: The physical dimensions and mounting options of the fan.

Fan Control and Regulation

Fan control is essential for optimizing fan performance and energy efficiency. It allows users to adjust fan speed and airflow to meet specific requirements. Common methods of fan control include:

- Manual Adjustment:Manually adjusting the fan speed using a switch or knob.

- Variable Frequency Drives (VFDs):VFDs regulate fan speed by controlling the frequency of the electrical current supplied to the fan motor.

- Temperature Sensors:Temperature sensors monitor the temperature of the environment and adjust fan speed accordingly to maintain a desired temperature.

Effective fan control systems consider factors such as:

- Load Variations:Fans must be able to adjust to changing load conditions to maintain optimal airflow.

- Energy Efficiency:Controlling fan speed can significantly reduce energy consumption, especially in variable load applications.

- Noise Control:Fan control can minimize noise levels by adjusting fan speed to meet airflow requirements.

Examples of Fan Control Systems

Various fan control systems are available, each tailored to specific applications:

- Constant Air Volume (CAV) Systems:CAV systems maintain a constant airflow regardless of load variations.

- Variable Air Volume (VAV) Systems:VAV systems adjust airflow based on load requirements, resulting in energy savings.

- Demand-Controlled Ventilation (DCV) Systems:DCV systems use sensors to monitor air quality and adjust fan speed to maintain optimal ventilation.

These systems enable precise fan control, optimizing performance and energy efficiency across a wide range of applications, including:

- HVAC Systems:Regulating airflow in heating, ventilation, and air conditioning systems.

- Industrial Processes:Controlling airflow in manufacturing processes to remove fumes and maintain safe working conditions.

- Data Centers:Optimizing airflow to cool servers and prevent overheating.

Fan Maintenance and Troubleshooting

To maintain optimal fan performance, regular maintenance is crucial. This includes cleaning, lubrication, and bearing inspection.

Cleaning involves removing dust, dirt, and debris from the fan blades, motor, and housing. Regular lubrication ensures smooth operation and reduces wear and tear. Bearing inspection involves checking for any signs of damage or excessive play.

Troubleshooting Common Fan Problems

Common fan problems include noise, vibration, and airflow issues. Noise can be caused by unbalanced blades, loose components, or worn bearings. Vibration can be caused by similar issues or by improper mounting.

Airflow issues can be caused by blockages in the fan housing or ducting, or by insufficient fan capacity. Troubleshooting involves identifying the root cause and implementing appropriate solutions.

Importance of Regular Maintenance and Inspection

Regular maintenance and inspection are essential for extending fan life and preventing failures. By addressing potential issues early on, costly repairs and downtime can be avoided.

Inspections should be conducted periodically, especially in critical applications where fan failure can have significant consequences.

FAQ Section

What are the key components of a fan?

Essential fan components include blades, motor, housing, and mounting system.

What factors affect fan performance?

Blade design, fan speed, and system resistance influence fan performance.

What are the common applications of fans?

Fans are used for ventilation, cooling, and air circulation in industries such as HVAC, electronics, and manufacturing.